Cogeneration Systems and Cutting-Edge Absorption Chillers

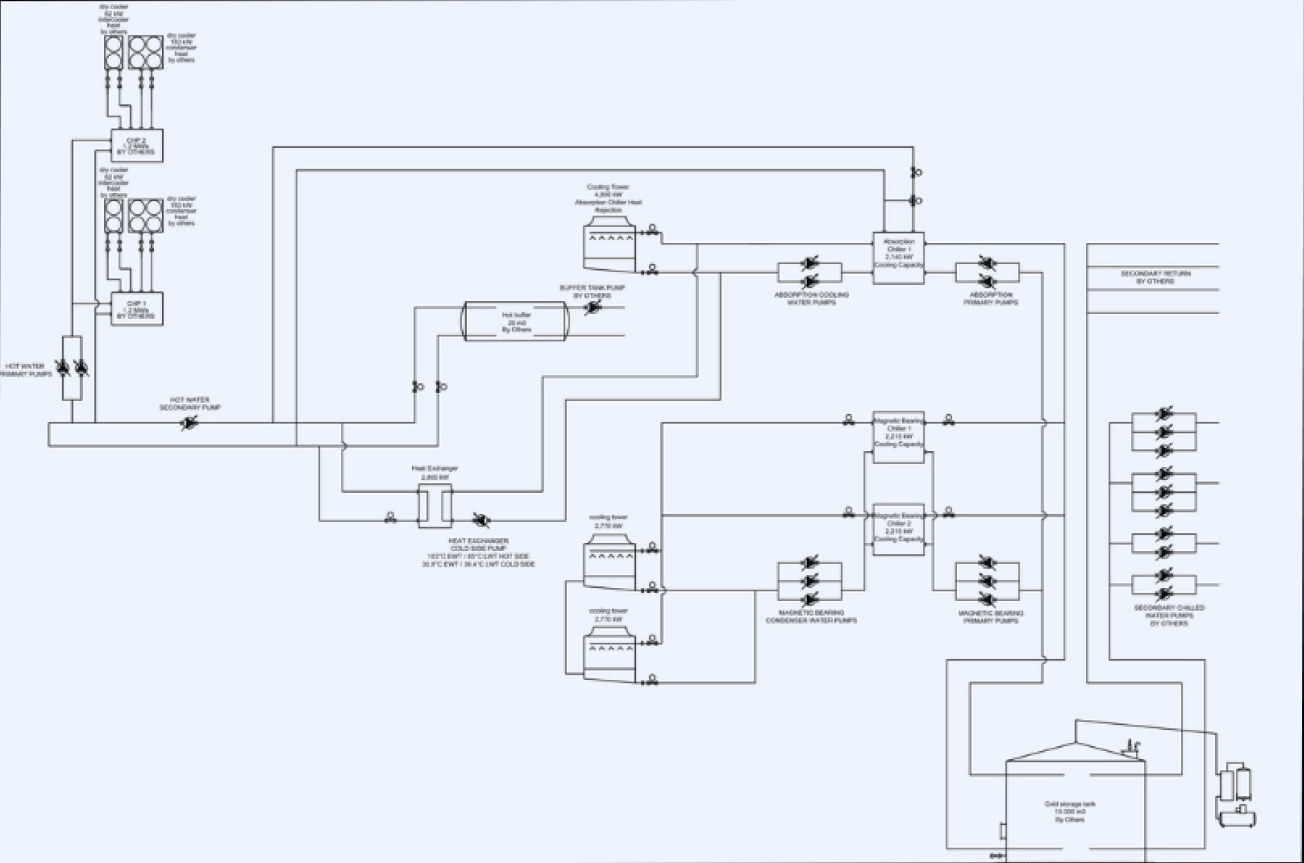

Fluid Cooling Systems (FCS) specializes in collaborating with manufacturers and developers of energy systems, particularly in cogeneration. In cogeneration setups, one or more gas turbines or natural gas engines drive generators sized for the electrical demand of a factory or campus, powering equipment, HVAC, process cooling, and heating and refrigeration systems. The hot exhaust from these generators can be efficiently harnessed to create hot water and/or steam and chilled water in absorption systems.

Within these cogeneration plants, the combined cooling, heating, and power are achieved through various means, including the turbine generator, flue gas heat, a gas-fired section, or a blend of both fuels. The adaptability extends to accepting even low-quality waste heat for certain applications. FCS collaborates closely with manufacturers to deliver the necessary infrastructure tailored to the specific requirements of each system.

Notably, some absorption chillers integrated into these cogeneration systems can produce chilled water/glycol to 32°F, making them ideal for factory processes that benefit from very cold chilled water service.

FCS plays a critical role in providing the essential balance of plant infrastructure and integration for cogeneration systems. Our collaborative efforts extend to working with power generator manufacturers, end customers, and power system developers to deliver a comprehensive and convenient solution for the effective utilization of waste heat and power generation.

Shuangliang absorption chillers. Steam, gas fired, and heat pumps are available.