What is Free Cooling?

Free Cooling is a dynamic, cost-effective method leveraging low external air temperatures for temperature control in industrial processes and HVAC systems. By harnessing naturally cooler outdoor air, free cooling eliminates the need for additional mechanical cooling equipment. Key factors influencing free cooling effectiveness include temperature, humidity, time of day, and cooling requirements.

Chiller Evaporator to Tower Water Integration

In chiller applications, free cooling becomes a reality through heat exchangers that transfer heat between cooling tower water and chilled water. The system is designed to allow compressors to stage off when the cooling tower water is colder than the desired chilled water temperature. This innovative approach can result in energy cost reductions of up to 70%, offering an environmentally friendly and cost-effective solution for both process and HVAC cooling.

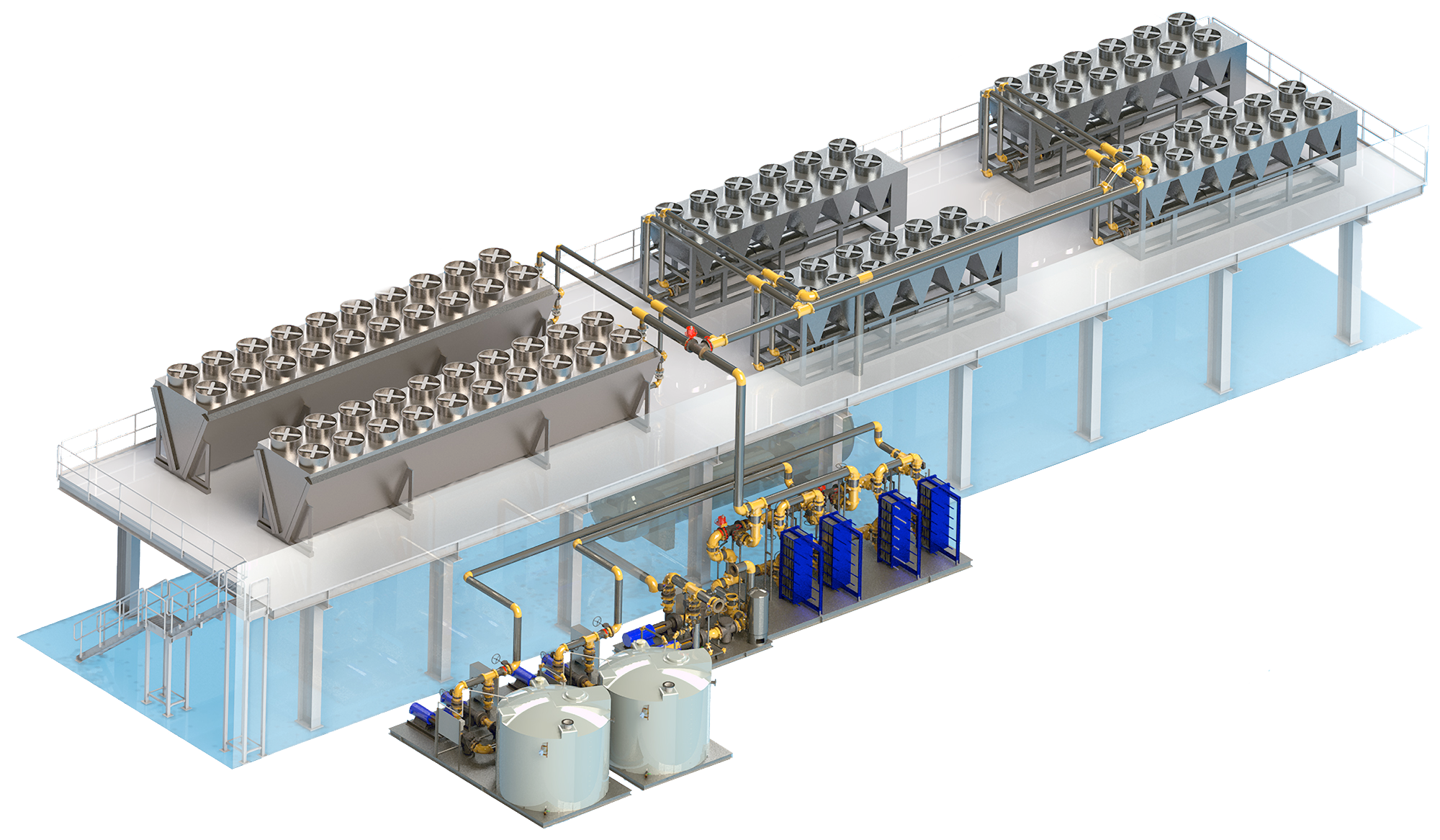

Free-Cooling from Air-Cooled Heat Exchangers (ACHEs)

Free cooling with ACHEs involves pumping chilled water through a heat exchanger exposed to outside air. Fans draw ambient air over the heat exchanger tubes, absorbing heat from the chilled water and cooling it down. The cooled water is then recirculated, providing an efficient cooling solution for buildings and industrial processes.

Cooling Tower Plate and Frame Heat Exchanger Integration

During cool outdoor temperatures, the chilled water system can leverage free cooling by bypassing the chiller and using a cooling tower with a plate and frame heat exchanger. This process circulates water through a heat exchange mechanism, transferring heat to the air and recirculating the cooled water back into the system. This approach significantly saves energy and enhances overall efficiency.

Economical Free Cooling with Air-Cooled Heat Exchangers

Free cooling, achieved by using low external air temperatures and an air-cooled heat exchanger, offers a cost-effective solution for meeting cooling loads. Installed in series or parallel with a chiller system's evaporator, an air-cooled heat exchanger operates automatically based on programmed set points, diverting water between the chiller and the heat exchanger as needed. This versatile system provides substantial energy savings during winter, mid-season, and peak ambient temperatures.

Experience efficiency, reliability, and long-term value with FCS Modular Mechanical Rooms—a cutting-edge solution tailored to your needs.