WHY FILTER?

Reliable filtration is a vital part of your cooling system and assures a clean hydronic system. Dirty utility water fouls heat exchangers and changes their approach temperature, performance and reduced system energy efficiency. Left untreated poor quality plant water can result in frequent and costly repairs. SPIREX™ Separators extend the life of your cooling and heating equipment and the entire water infrastructure, and require less chemical treatment to maintain the system.

SEQUENCE OF OPERATION

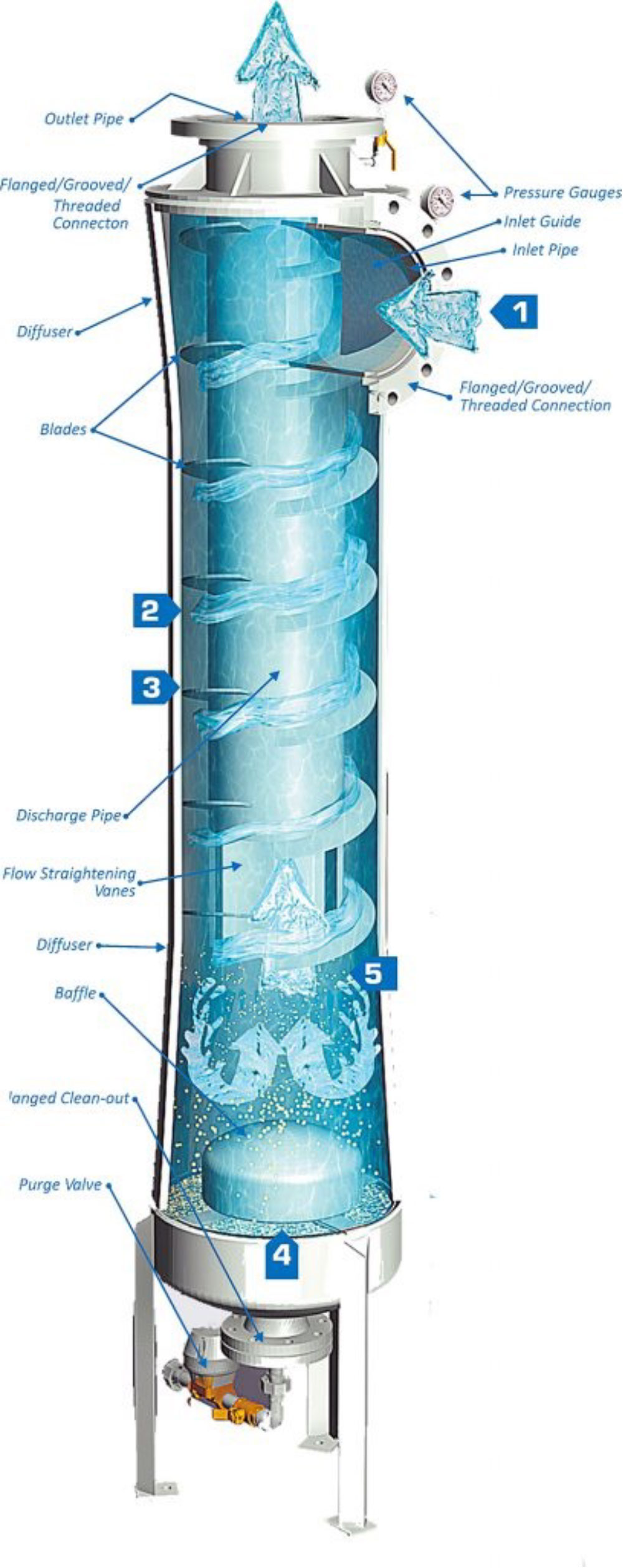

1.

Fluid flows into the inlet pipe and into the bell-cone. the engineered tangential entry and sloped inlet guide steers the fluid into the SPIREX™ body where it spins inside the vessel.

2.

As fluid contacts the blades, it is guided in a continuous spiral motion to the bottom of the vessel. Liquid is prevented from flowing down the center of the SPIREX™ Separator. The spinning action causes particles to move to the outer walls.

3.

The spacing between guides and walls allow larger particles to easily move down the wall. The design causes particulate to experience in excess of 5Gs or force.

4.

Particulate travels down below the bell cone where it slows down and settles out of solution. An automatic or manually operated Purge Valve removes the settled particles.

5.

The slower, and now cleaner fluid travels to the exit above the baffle dome. Here the fluid meets SPIREX™ Straightening Vanes that stop the spiraling action and produces a straight flow into the piping system resulting in less friction and pressure drop.

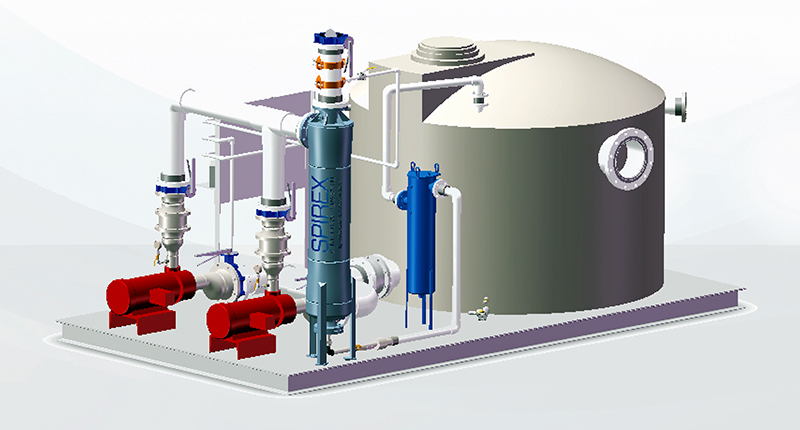

WATER QUALITY SOLUTIONS

The SPIREX™ Centrifugal Separator is a patent-pending device, intelligently designed using tools as Computational Fluid Dynamics (CFD) to model and optimize velocities for proper separation and pressure-drop. Our innovative design assures maximum performance and system efficiency. Durable industrial construction makes the SPIREX™ Centrifugal Separator a key component in your infrastructure strategy.

WATER QUALITY SOLUTIONS

Open-Loop Tower Systems

Spray-Water Systems

Pre-Filtration Systems

Mechanical-Seal Support Systems

Nozzle Applications

Quench-Tank Recirculation

River and Lake Water Systems

Utility Water Cooling Loops

INDUSTRIES WE SERVE

Industrial and Commercial

Process Cooling Systems

Automotive

Chemical Processing

Ethanol Plants

Food Processing

Primary Metals

Municipals Water Service

Wash Systems

Oil and Gas

Mining Operations

Pulp and Paper Mills

Utility Power Plants