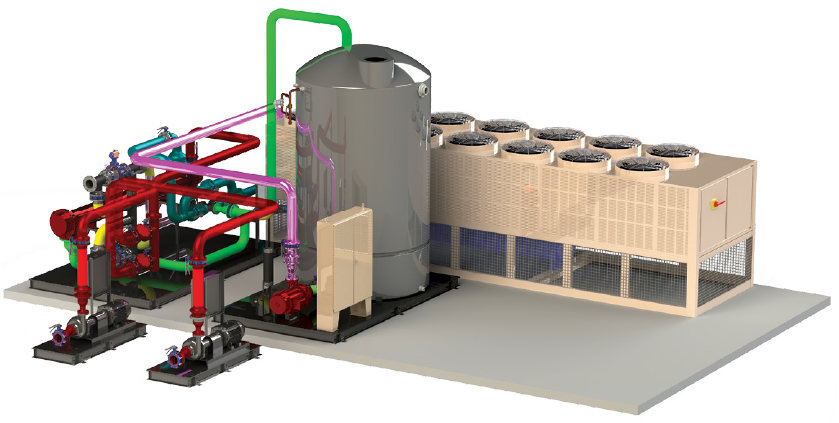

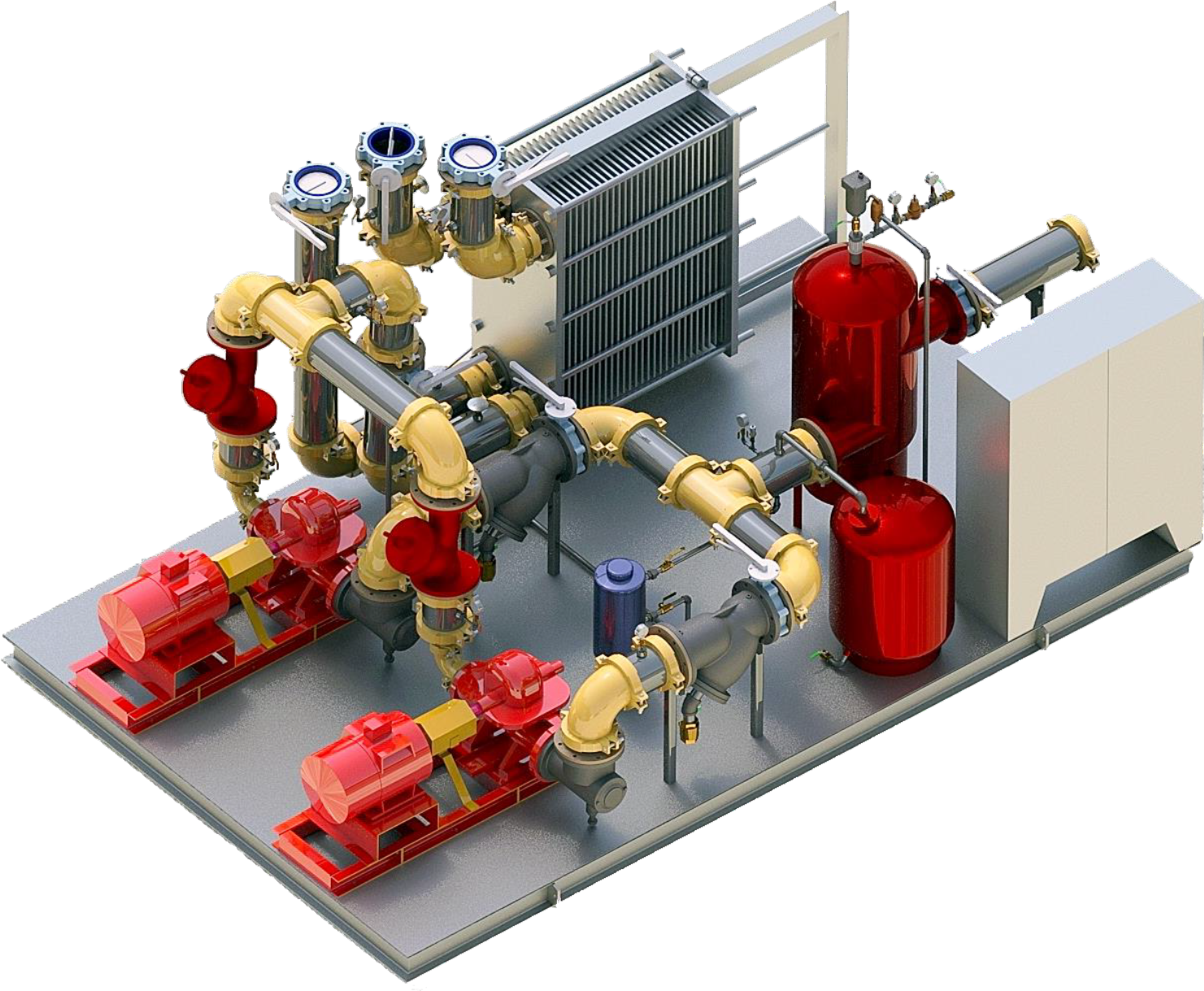

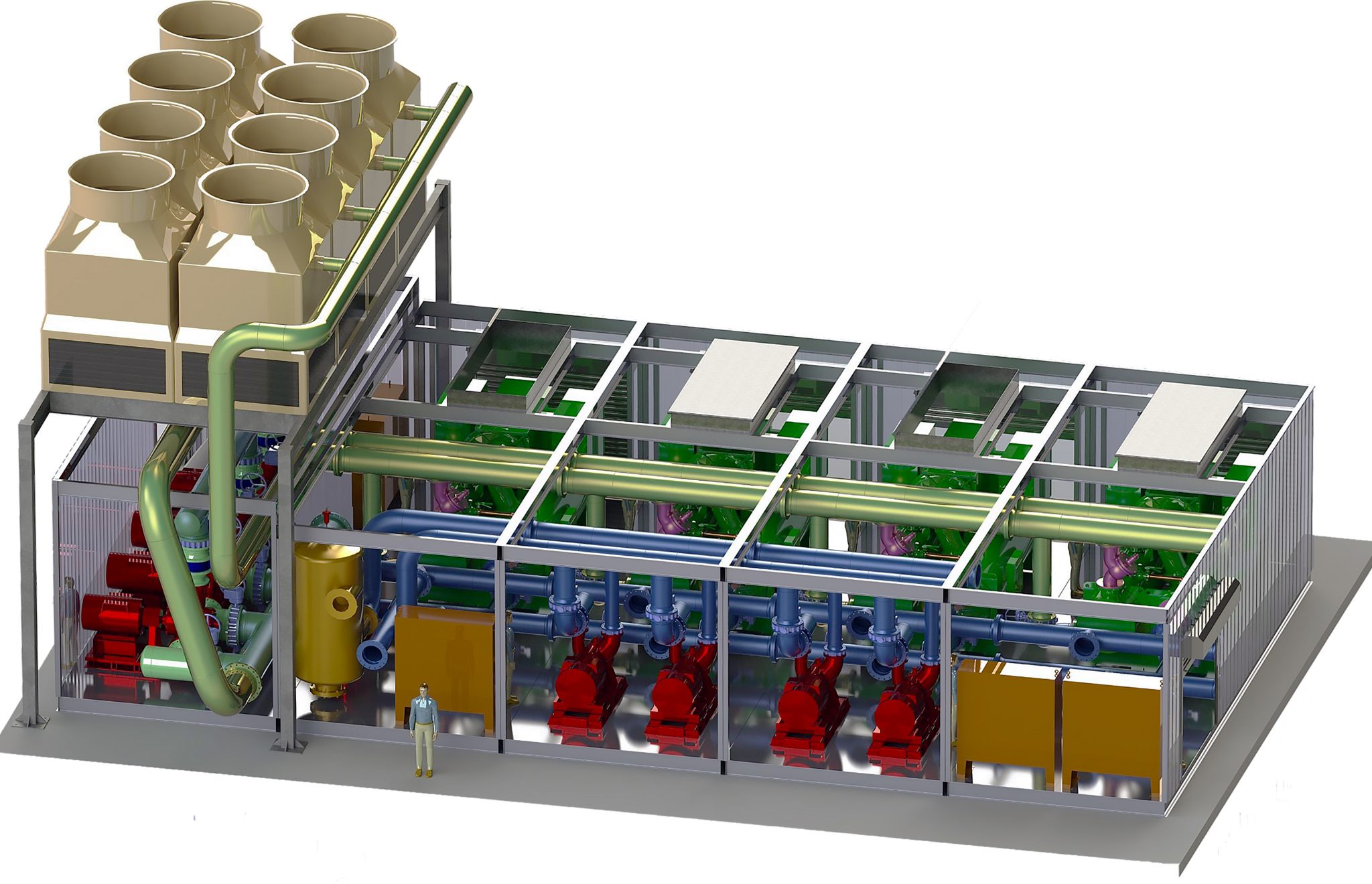

Process Cooling and Fluid Handling Systems

Fluid Cooling Systems has built a sterling reputation for engineering and delivering premium, integrated cooling solutions. Collaborating closely with industrial and HVAC clients, we address diverse cooling, heat transfer, and heat recovery needs. We pride ourselves on being cost-effective, reliable, and delivering high-quality, energy-efficient systems.

Quality Above All

We are ISO certified with quality controls in place from project management to safety regulations. Our approach isn't driven by price; instead, we focus on designing and building lasting solutions using the highest quality materials and components.

Customers First

We educate our customers so they are comfortable with our recommendations and appreciate our selections and built-in benefits. They appreciate knowing how and why we developed our solutions and it’s a great way to build trust.

Strength In Partnerships

We approach our business relationships as a partnership with our customers and vendors alike, gaining a thorough understanding of products, processes, specifications and budgets, and working toward common goals.